In recent years, CBD has made a boom in the modern world. Despite the popularity of this supplement, many individuals are still confused between marihuana and hemp.

The former contains more than 0.3 % of THC, and it’s only grown and legalized in certain states. The latter contains less than 0.3 % THC and must be grown under a special program. Plenty of people are curious about the CBD extraction process.

Make sure you learn how it’s extracted from hemp oil and plants.

Different extraction methods

Cannabidiol is among the three major compounds found in the Cannabis Sativa plant, which has unquestionably increased in popularity over the past years due to its range of physical and mental health benefits. Nevertheless, the extraction of CBD from hemp plants isn’t exactly straightforward, as the medicinal qualities of the plant are incredibly vulnerable to damage. Read this article for an overview of the uses and effectiveness of CBD.

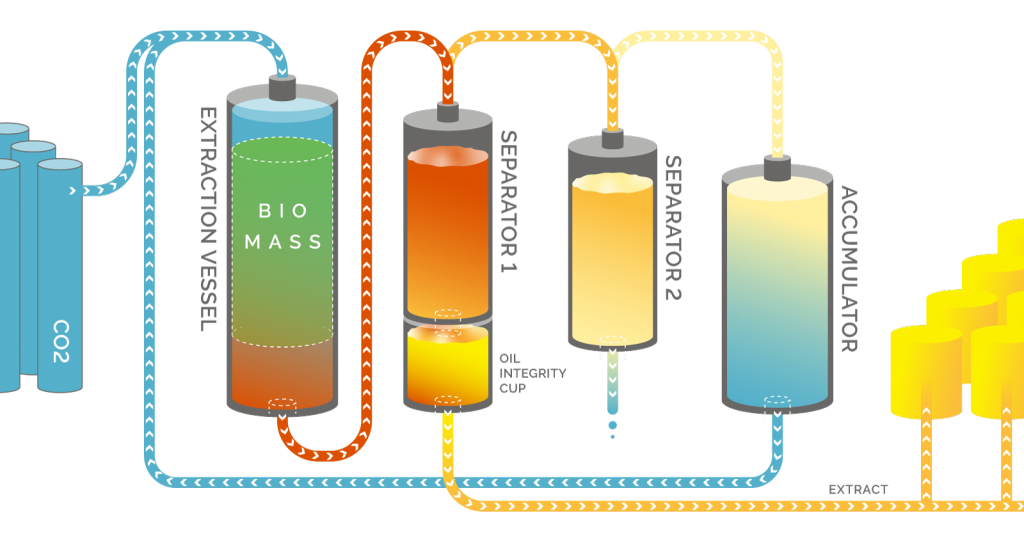

The most prominent extraction methods are CO2 and ethanol. The former involves filtration of plants through multiple chambers, which control pressure and temperature. It relies on carbon dioxide for the isolation of cannabinoids under freezing temperatures. Cooled carbon dioxide is powerful enough to cool CBD oil while leaving no residue or chemicals behind. The isolation efficiency of CO2 extraction is ninety percent.

The best way to isolate compounds from the plant, including CBD, is for the extracted oil to undergo distillation after its extraction. The first step is winterization, after which short path distillation follows. Winterization is a term that describes the removal of unwanted elements, which got extracted from the hemp plant, like lipids, waxes, and fats. It’s only necessary when the oil extraction is performed at high temperature/pressure, powerful enough to extract all plant material, not just the one you need.

Moreover, the oil that’s extracted is crude, hence requiring refining. It’s then mixed with 200-proof alcohol and stirred until both ingredients unify. The following step is to have it placed in a freezer where it will stay overnight. The appearance of the mixture in the morning should be cloudy, indicating it’s prepared for filtration.

The filtration process is usually performed with a Buchner Funnel, removing all the unnecessary elements. Finally, it’s time to eliminate the alcohol by applying heat. Further refining and isolation of CBD can be performed via short path distillation.

In contrast, ethanol extraction is a different method, which involves soaking the hemp plant in alcohol to extract cannabidiol. The purity of cannabidiol extracted with ethanol can reach 99 percent, meaning the final product quality is higher than the CO2 method. Visit this website, https://sciencing.com/uses-carbon-dioxide-gas-6364016.html, to learn about the uses of carbon dioxide gas.

Another extraction method worth mentioning is oil extraction, although this method lacks the popularity of the previous two methodologies. It’s mainly used at home by heating and cooking a hemp plant with carrier oils, such as olive or coconut oil, which extracts the required cannabinoids.

Both most popular methodologies come with their own sets of pros and cons. Regarding the equipment, the CO2 method requires costlier equipment in return for terpene preservation and no residual solvents. Conversely, ethanol equipment is inexpensive and fast, but it requires secondary processing.

How is CBD oil made?

The journey of making CBD oil consists of several steps, the first of which is planting the hemp plant. Prior to sowing the seeds into the ground, farmers must prepare the soil and have it tested for herbicides. These crops can be planted next to each other at a distance of at least four inches. They produce biomass, referring to the matter that goes back to the soil in order to feed nutrients back into it.

The hemp plant is planted in late May to early June, and it grows quickly in a 60-day period. In general, these crops are harvested in October, based on the climate in a given state. If you wish to learn how to extract CBD from hemp oil, you should first learn about the hemp plant. Prior to the official harvest, crop samples need to be tested by the agriculture department of the state to make sure THC levels are below 0,3 %.

Following the harvest, these plants should undergo a curing process of three to four weeks, during which they should air dry. Next is the extraction process that we already explained. After extracting the purest form of cannabidiol, you should combine it with other ingredients like carrier oils to create high-quality products with high bioavailability. The final step of the journey is lab testing by sending samples to a laboratory to get them examined for potency and purity.

Final thoughts

Different extraction methods come with various benefits.

Weighing the pros and cons of each one is essential!